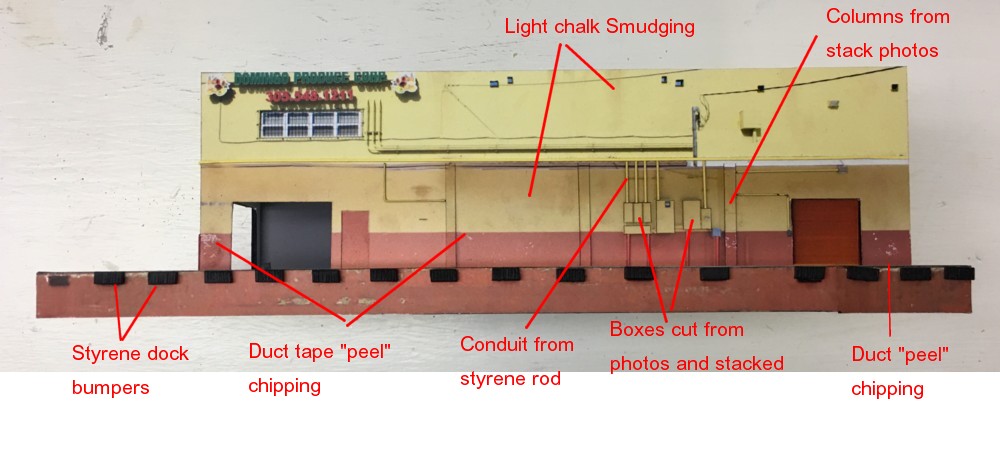

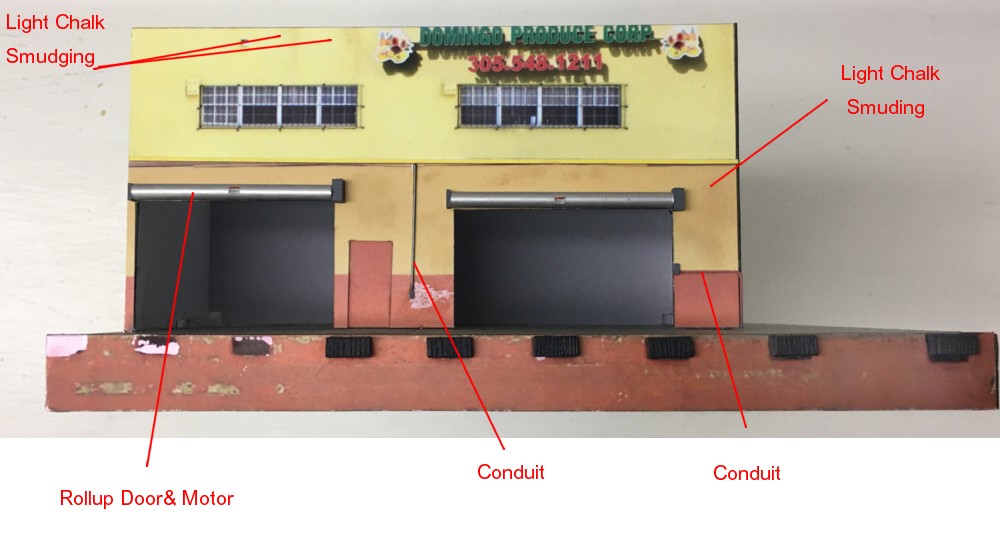

An appealing aspect of the area of Miami I’m modeling is the quiet, calm, melancholy atmosphere along the 22nd Street corridor. I particularly like the late afternoons when the shadows grow long and it takes on an almost Hopperesque atmosphere. My next project will be modeling the First Coast of Miami (produce) scene shown above (the courtyard framed by the two box trucks). You’re looking west down 22nd Street. The Domingo Produce structure, which I just finished, would be just out of view to the right.