How to Solder

Soldering is one of the more useful skills when it comes to building a model railroad. It can also be intimidating and a source of frustration for those that haven’t done it before. Like anything else, it really is not that difficult IF you use the right materials and techniques.

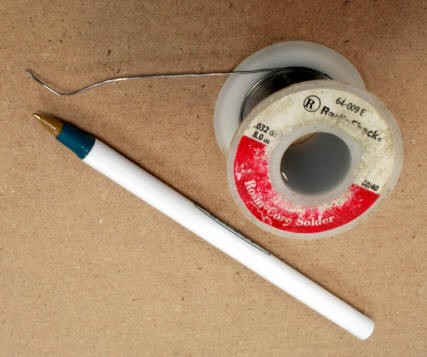

Tip 1: Use a HOT soldering gun. I prefer a 40 watt pencil gun. These are available from Radio Shack for about ten dollars or through Amazon.

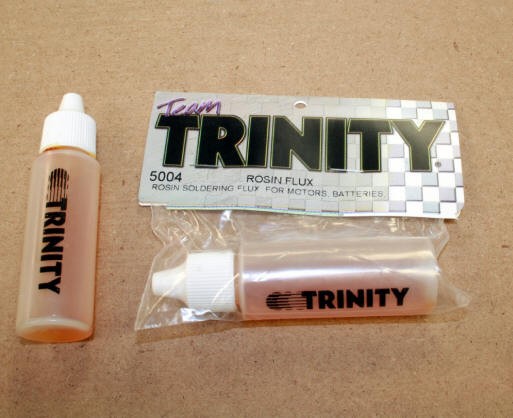

Tip 2: Use a high quality liquid flux for quick and reliable heat transfer. This is one of the biggest difference makers in terms of getting a successful result. Using flux will largely eliminate the problem of having your plastic ties melt long before the rail is hot enough to melt the solder. I prefer liquid flux from Team Trinity (part #5004). http://www.teamtrinity.com/ When applying flux, a “dab will do you”. A small drop on the objects being soldered will do the job. Don’t put on too much or you’ll have a brown residue that will need to be cleaned up later.

Tip 3: Use thin solder. I prefer .032″ diameter available at Radio Shack.

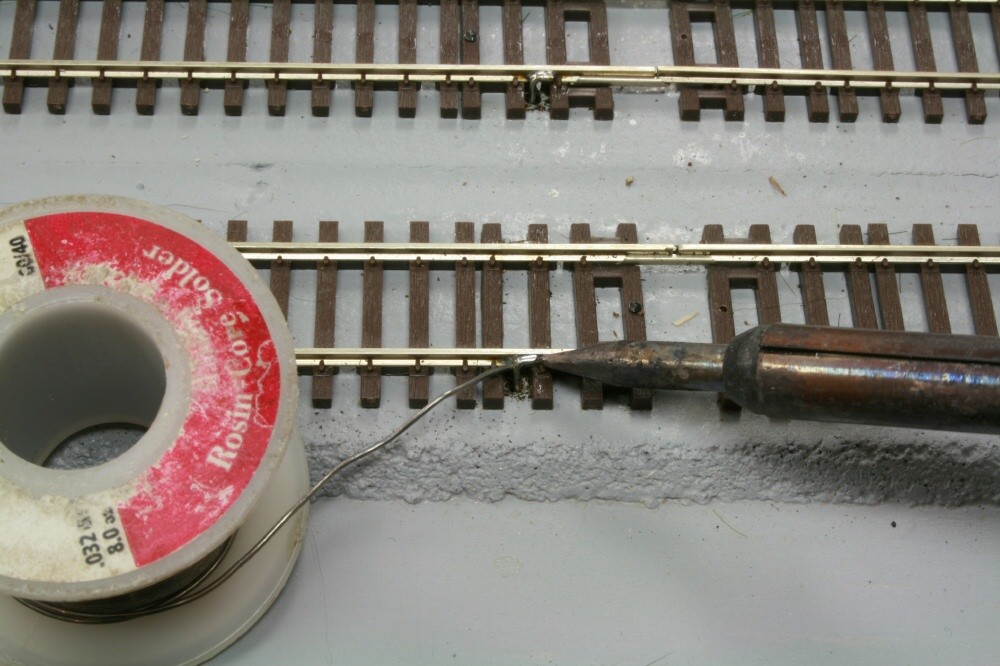

Tip 4: Make sure the items being soldered are reasonably clean and free of paint, oxidation and residue.

Tip 5: Let BOTH of the OBJECTS BEING SOLDERED melt the solder, NOT the tip of the gun. For example, if you are soldering a wire to the rail, put the wire tight against the rail, apply a drop of flux and hold the soldering iron tip tight against the wire pushing it tight against rail. Make sure both objects are hot enough to melt the solder. They should heat up quickly. If one is hot and the other is cold you may get a partial bond but it will likely be of questionable integrity. When both objects being soldered are hot, touch your solder against the object being heated and in a few seconds the solder should should flow like water. Finally, remove the gun and let the solder cool.

Final Tip: Keep your soldering iron tip clean. After a few uses you’ll see some charcoal type material building up on the tip of your gun. A few passes with jewelers file will quickly clean if off. If you don’t keep it clean you’ll quickly notice it takes much longer to heat things up.

Safety Reminder: Remember to turn off your gun before leaving the room. Never leave a hot soldering gun un-attended.