My product of choice when it comes to turnouts are those from Micro Engineering. They are mechanically sound, highly detailed, and the points are spring loaded allowing them to be thrown with a simple flip of the finger. As solid as they are, there are a few enhancements that make a good part even better.

- Fill in the holes in the throw bar with modeler’s putty

- Sometimes the tip of the point has a slight curl to it. Use tweezers to gently bend the points straight so they sit tight against the stock rail. Give a few light passes with a file to the point tip to give it a more of a knife edge profile. This further reduces the risk that a wheel will pick the points.

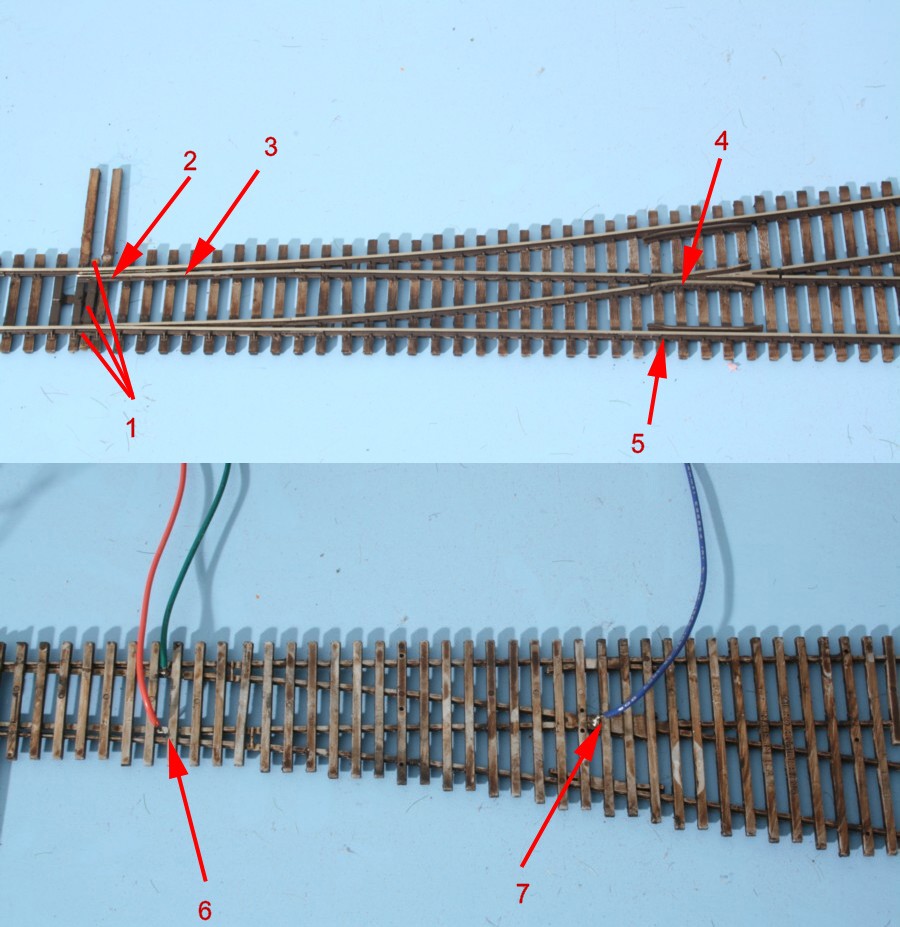

- Reinforcing bolt plate from Proto 87 Stores

- Bolt plate from Micro Engineering (this comes with the turnout)

- Joint bar from Details West (pn RB 933)

- The points rely on mechanical connections to receive power. On occasion, dirt or oxidation will break the connection, the points go mechanically ‘dead’, and you may get some locomotive stalling. Carefully solder a stranded feeder to the heal of the points. Be careful not to get solder into the joint. When threading the feeder wire through the hole you drilled in the sub-roadbed, don’t glue the ballast, leave it loose so as to allow enough flex in the wires that the points will still swing. Note that adding these feeders is purely optional as less then ten percent of your turnouts will have an issue where this is necessary.

- Power tap to frog in case you want to feed power to it via a “Frog Juicer” or through a switch machine. You may not need this but it’s easier to add the wire before installation than find out you need it after the fact.