I was honored to be a guest on my buddy Ray Arnot’s latest “Around The Layout” podcast. Always a fun time! You can listen to it HERE.

For a full listing of all of Ray’s Podcasts visit his site HERE.

Looking east down 22nd Street on my Downtown Spur layout. The layout is located in an eighteen by eighteen foot room and has thirteen turnouts.

Switching layouts and moderate-size branch line railroads aren’t about “settling”. They aren’t the sole province of the space-deprived or financially strapped.

They’re about access. They provide an easy entry portal into the hobby. Typically there’s an immediate leap to space and budget when we think of assets. Model railroading, approached rationally, isn’t that expensive and is within reach of even a high school student with a summer job.

Assets aren’t only about space and money though. Sparse assets in other areas do provide a barrier to getting into the hobby and that’s where the simpler layouts offer a workaround. Most modelers are financially comfortable. They can afford cable, Friday nights with the family at The Olive Garden, and an SUV in the driveway. Time isn’t the issue either. I have too many active-duty military friends who are modelers for me to believe that. Everybody can find at least a few hours a week. The problem is you need other assets to get a functional layout up and running, and that’s where people get stuck. Even if you have space, time, and money (and almost everyone does) you still need:

-Basic Skills

-Energy

-Focus

Those new to the hobby would be wise to attain some basic skills and confidence before leaping into a basement-filling railroad project. If you’ve spent 75 minutes in the car morning and night, having the energy and motivation to work on modeling is questionable. Screen and device distraction is real and erodes our ability to focus. Switching layouts require less skill, energy, and focus.

My Modern Era Switching Layout series lays down a path from armchair modeler or newcomer to getting trains running on a layout.

We’re entering the new year. Why not set the achievable goal of getting at least the bones of switching layout built and trains running? Scenery and structures can wait until 2025. I have an entire series of books to guide you through the process. The Fruitland Team Track or CIS Light designs in the 8 Track Plans book are can’t loose starting points. Get the bench work up and lay down some Peco code 70 with Unifrog turnouts. Pick up a decent Athearn genesis or Rapido loco and start slamming some cars. Get your hands dirty. Make your mistakes. Have some fun.

I’ll even sweeten the pot. Any reader that gets that far with their layout, and emails me that they’re bored, will get a full refund on the cost of their blog subscription fee.

Ben Sullivan stands in front of his masterful rendition of the Georgetown Branch’s Rock Creek Viaduct. Results like this come from being in the game long term, making mistakes, learning from them, and moving forward. Attitude and approach to the hobby goes a long way.

The last two weekends were particularly enjoyable for me, both being spent visiting with hobby veterans Ben Sullivan and Kelly Regan. Each is modeling one of my favorite prototypes, B&O’s Georgetown Branch. Although they are excellent builders, what I’ve enjoyed most about my visits is seeing their overall approach and attitude as well as how they collaborate on philosophy, photo sharing, and helping one another out.

It’s worth checking our attitudes and approach to the hobby from time to time. Doing so insures we continue to find it satisfying and also results in better models over the long term. I’ve seen the full spectrum over the decades. For some, none of their efforts are ever good enough (to them at least) which leads to constantly starting over and never getting anything done. On the other end of the spectrum you have those that crank stuff out like an assembly line but never take stock of what they’re doing. When this happens the quality of the work doesn’t improve over time. Finally, you have the chest-pounding braggarts, which thankfully are in the minority.

What is a healthy approach? First, it’s being in the game as I wrote in my December 11th blog. Build stuff consistently. In terms of attitude, for me, I’ve come to this:

“I recognize each modeling effort as representing the best I could do given my skill level at the time and give myself a pat on the back for being in the game. I don’t get too high or too low. Finally, I dispassionately examine my work and make mental notes for subtle improvements to try on the next go around.”

When I complete a project, I put it on the layout and live with it for a few years. I have had three or four cases where I made a second pass at a model and replaced the original effort. Doing so was fun but it’s rare and I only do it after a few years have passed.

Getting back to Kelly and Ben the one thing we talked about a lot was our past layout building snafu’s and how, without them and the lessons they taught us, it would be impossible to improve. You simply can’t get a sense of spatial relationships, the time involved in completing various construction tasks, the mechanics of construction, and hidden landmines from parking on social media and forums all day. While both Ben and Kelly start their track planning in CAD, they only use that as a starting point and then quickly move on to a heavy reliance on full size mock-ups of track and structures to test the final composition.

A few lessons from these “battle-scarred veterans” I noticed were:

Ben had just finished an exquisite scratch-built model of the Rock Creek viaduct (see lead photo). It was rivet-by-rivet perfect. However, with experience, you learn there are times you need to split from the prototype. He’d put meticulous effort into modeling the nut-bolt-washer castings. On the prototype, they’re the same color as the surrounding wood, rendering them all but invisible. Ben subtly highlighted the NBW parts, painting them a slightly lighter color to create contrast. The hue was just different enough to get the job done without being in your face. The end result was impressive. It really made the model snap.

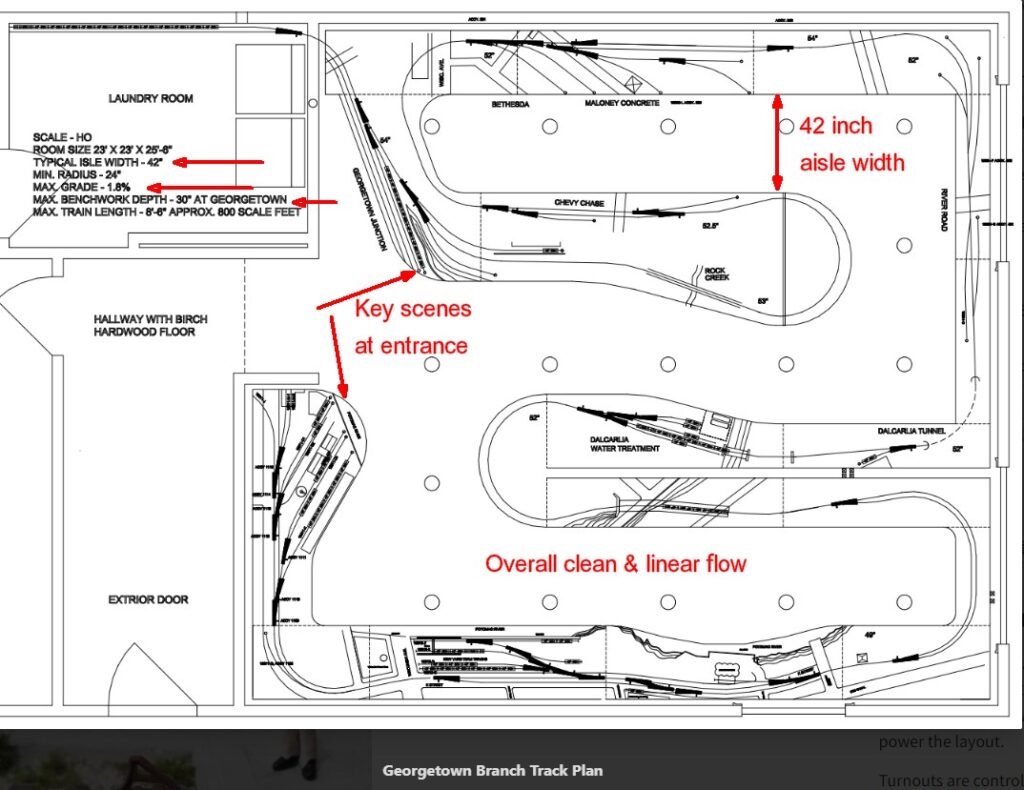

Shown above is Kelly’s track plan, a design I’d consider excellent for reasons that go beyond what you see on paper. This design didn’t come from endless philosophical debates on the forums but rather from having built several previous layouts and learning some hard lessons. A few points to take note of:

-The two signature scenes are located on each side of the door, not hidden in the back.

-Aisles are generous.

-The room is CLEAN!

-The backdrop was kept deliberately low.

-You can easily and comfortably follow a train down the branch.

-Sight lines are controlled.

-Grades are modest.

Kelly stands in front of his Georgetown scene. Note the open look, the low backdrop, the impact of the overall cleanliness of the room.

The only way to truly improve over the decades is to be in the game and get the battle scars that go along with doing so. If you don’t occasionally examine your work and look for areas of improvement you won’t get better. On the flip side, constantly beating yourself up is unfair and self-defeating.

What was that old commercial, “Be Like Mike”? I’ll revise that and say be like Ben and Kelly.

You can see more of their work here:

Kelly’s 3D Store (note the excellent wheel stops)

One of my earliest efforts, “8 Track Plans For a Spare Room” got panned by reviewers. With the detachment that comes with time, I consider the plans within it some of my better lifetime designs. Go figure.

“If you can’t stand the heat…..then get out of the oven”. It’s a good adage to keep in mind for anyone considering becoming a published book author. No matter who you are, there will be a percentage that is “not impressed”. On Michael Connelly’s famous book, “Black Echo”, one reviewer, “Mr. G.”, posted the following 1 star review on Amazon “Boring plot, terrible dialogue, cheesy characterizations. Was genuinely surprised by how bad it was.”

I’m sure Michael isn’t losing much sleep over Mr. G’s opinion considering both Amazon and Netflix have top rated series based on his books.

My eleventh book, one on structures published by Kalmbach, hits the shelves in May. It’s been an interesting ride from the standpoint that it’s difficult, if not impossible, to predict what subjects will catch on and which ones won’t. I wouldn’t say it was a “phoned-in” effort, but my operations book rolled off the typewriter fairly easily. It was just an off-the-cuff idea that went on to become my best seller.

By contrast, what I’d consider one of my better efforts from a content point of view, the one on designs for a spare room has gotten mixed feedback, the lowest ranked reviews, and experienced tepid sales. One less-than-impressed purchaser wrote: “Not worth the money. All the plans are for the same 11’x12′ room (which is true). Only one plan allows for continuous running (factually incorrect, three are continuous run). All the plans are variations on the same theme (factually incorrect. Each is an entirely different theme). Nothing really innovative or clever. Not worth the money”. Well then, tell me what you really think!

It all comes down to different strokes for different folks. I’m a little surprised how emotionally detached I am from how a book is received. I put all of my effort, and it’s a LOT of effort, into satisfying myself that what I’ve come up with is my best effort. That’s all I can control. Once it hits print, I wash my hands of it and don’t go back to re-read them.

Stepping to the other side of the fence, putting myself in the position of a reviewer, I’m no different. We watched a movie a few weeks ago, which I thought was great. I looked up the reviews on IMdB and was surprised to see it got 2 ½ stars and terrible reviews. The following week we watched an old De Niro flick which I thought was awful. Guess what? 4.8 stars and rave reviews!

The room footprint in the Spare Room design book is by far the most common I see in my design and construction business. I honestly hadn’t looked at it in ten years. On a whim I dusted it off and gave it a read. Yes, it has rough edges that come with me being a newbie in self-publishing when I wrote it fifteen years ago. In retrospect, I should probably should have expanded on the text a little and made the font smaller. Water under the bridge. When I look at the content though, the pure meat and substance, I do consider the nine plans inside to be pretty darn solid if I do say so myself, some of my best work. I stand by them. Shown below is one example.

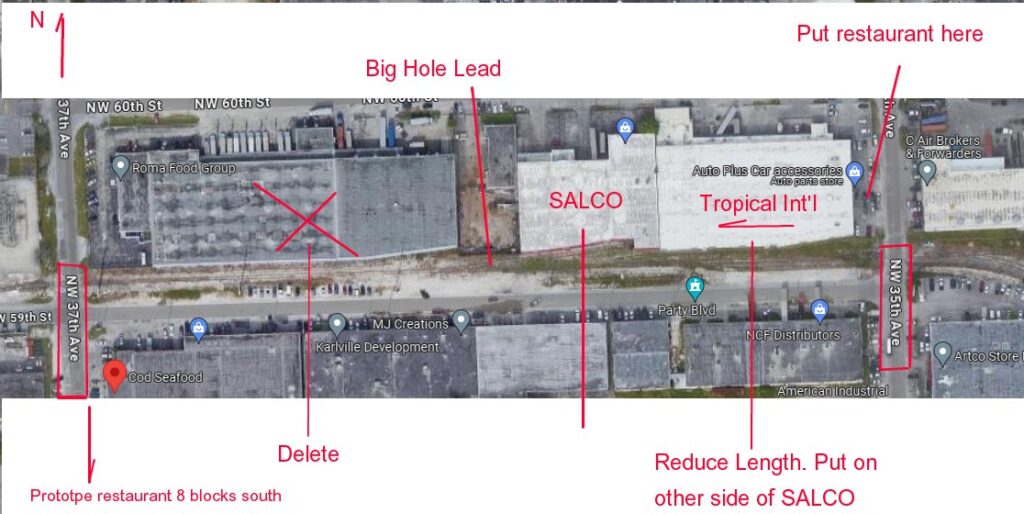

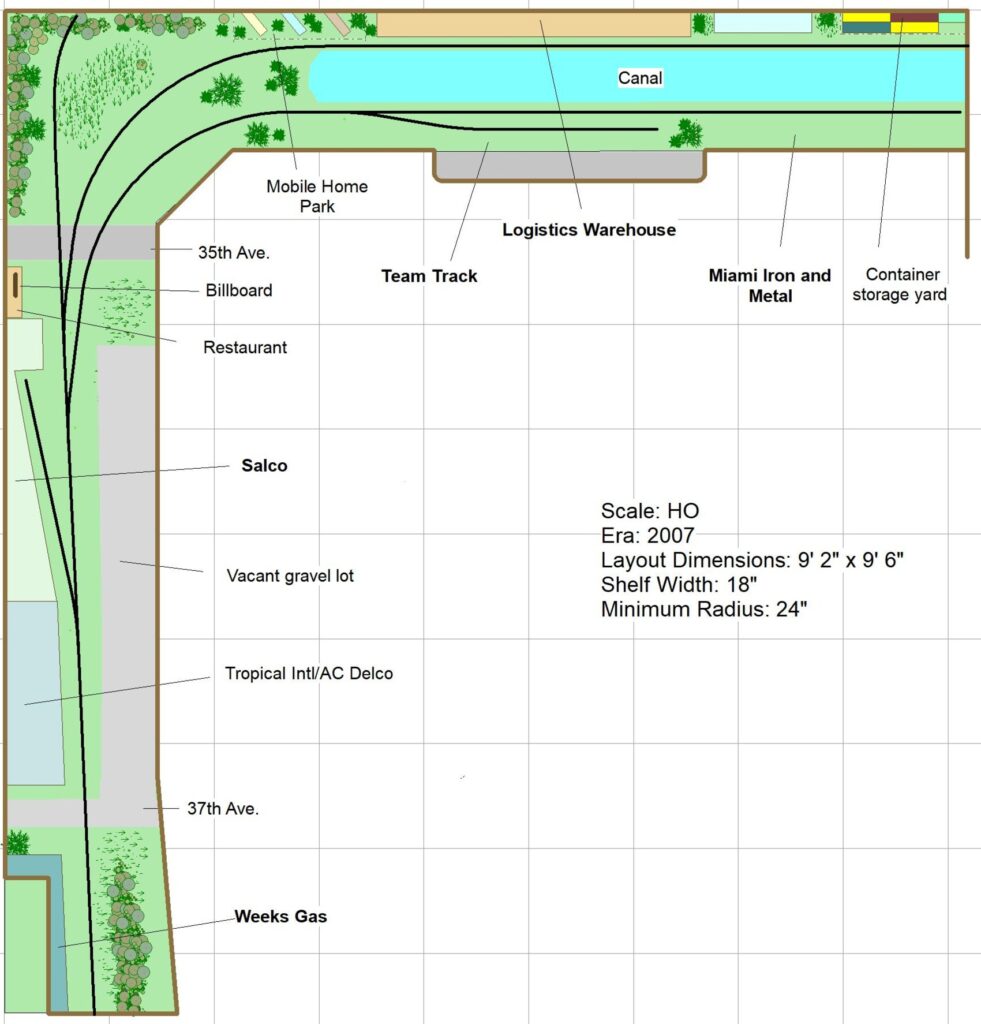

The Big Hole Lead in Miami’s East Rail industrial park serves as the inspiration for the left leg of the layout. While only two blocks long, it’s still way too large to fit on a ten foot long layout shelf. Decisions need to be made to compose a scene that A) fits B) is recognizable C) isn’t overly compressed and D) doesn’t resort to caricature. Follow along as I walk through how I approached composing the scene.

The ultimate end game for prototype modelers or, to be more accurate with labels, “proto-freelancers” (which we all are to an extent), is to create scenes that are recognizable. When we’re done, we want to be able to stand back, look at our work and think, “that looks like East Rail, Vernon, etc”. Achieving this requires employing what I’d consider the most difficult skill to master, scene composition. Even the most basic prototype subject is enormous when compared to the miniscule space we have available. Artistic and compositional decisions need to be made. It’s at this fork in the road that the wheels come off of the bus for many modelers. The two things that need to happen are simply steps they don’t want to take. It’s the proverbial dog chasing its tail in circles, taking the same approaches and hoping for different results.

So, what are the two critical steps? First, decisions need to be made to eliminate subjects from scenes, even compelling ones. Elements need to be sent to the cutting room floor for the betterment of the overall goal. Without doing so, scenes become overly compressed and appear toylike, very toylike. For whatever reason, the mere suggestion of “cropping” brings visible beads of sweat to many modeler’s foreheads.

The second element of achieving effective composition is getting the necessary training. In particular, finding better sources of information, specifically from the art world. It’s unlikely that ChooChooBob1951 on the forums has a workable answer. The presenter of a lecture on scene composition at your local art museum, likely with a Masters in Art, does. As with the cropping suggestion, the mere suggestion of attending composition and visual literacy lectures lands with the same resounding thud. The default plan of action typically being plopping in front of a screen and putting the issue out on a forum for dozens of strangers, all of who know less than you, to weigh in on.

Shown above is an aerial image of the section of East Rail I used as inspiration for the left leg of the layout. As basic as it is, it’s still way too big to fit on a ten foot long shelf. First, I deleted the large warehouse on the left. SALCO is the signature structure and is small enough to model to scale. The primary look of this scene is that of one long wall so I need to fill things out with one more warehouse. In this case I selected Tropical International. The track geometry on the model was such that I needed to relocate Tropical to the other side of SALCO, no big deal since it takes the place of the warehouse I previously eliminated. I also needed to cut the length of Tropical by half. Since the structure is a very uniform, nondescript cube, doing so didn’t stand out. At this point I thought I was done, built the cores of SALCO and Tropical Int’l, and put them in place.

Tropical International has identical architecture to SALCO but is a separate building and is located just to the east. In order to make it fit, I moved it to the west side of SALCO on my layout. Since both structures look similar, the swap isn’t noticeable.

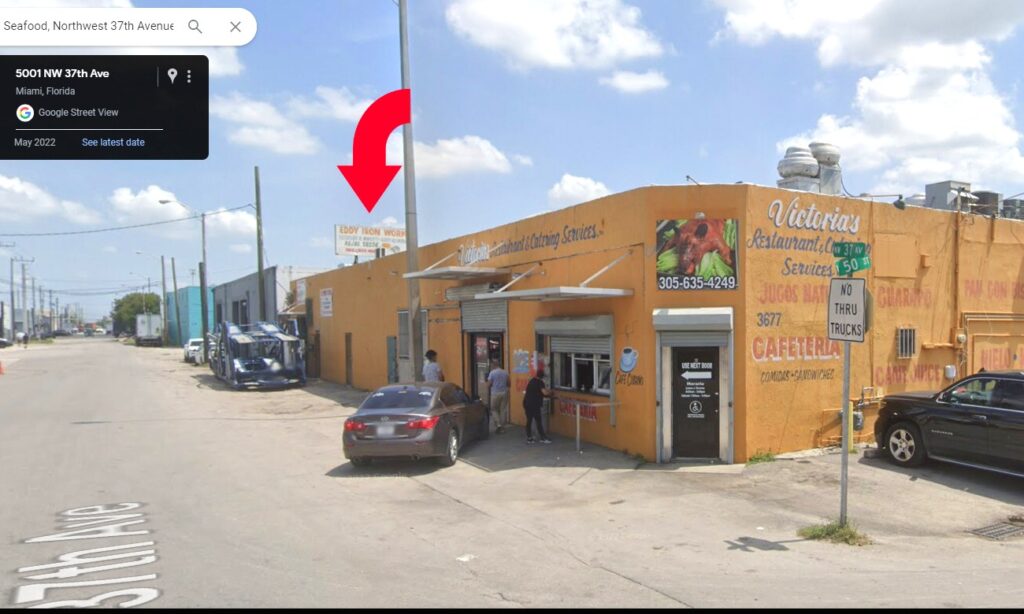

Something seemed “off” in a hard to define way. There was a barren, desolate look to the scene. It needed a dose of human activity. This is where things get super tricky and it’s a thread the needle, high wire act of not tilting towards caricature. When I’m stuck, I look to the prototype, find something that is the rule, not the exception, and copy it.

Industrial regions are populated by workers and they need to go somewhere for lunch. In this section of Miami food trucks are less common. Instead, you see a lot of small mom and pop restaurants. 37th Avenue is lined with them. Putting a small one in the scene added the necessary “snap” without looking out of place. I just picked a prototype restaurant a few blocks south on 37th Avenue.

I also wanted a Spanish language billboard to add a regional stamp to the scene. I did so on the orignal East Rail layout. The problem is that the roads through this area carry lower traffic volume and it’s not that plausible to have a large advertisement in an area that wouldn’t see much traffic. In a subtle way, a billboard would be too “model railroady”. Again, a virtual trip to the prototype can often solve problems like this. Marching the Google Streetview icon down 37th Avenue turned up this large sign for Eddy Iron Work (I guess the sign shop wasn’t concerned about spelling). It’s large enough to be visible, is plausible, but smaller than a billboard.

Here’s the left side of the scene showing the completed cores of the two warehouses.

A view from the right.

A mockup of the restaurant and large, Spanish language, sign. Note the way it’s set back to allow for parking and to break up the long, uniform, expanse of walls to the left.

Finally, here’s the updated track plan. As a side note, for a layout this small, designing via sketches and the computer is not very effective (which is my third, and final, suggestion that modelers hate to hear). You’ll get far better results mocking it up in 3D. Get your bench work up, place some loose track down, and move things around to test various compositions.