Your switch list looks easy enough, just switch one industry, a logistics warehouse in Miami’s East Rail industrial park. Three cars are spotted there and you have three incoming loads. Pull three cars, set them aside, spot the incomings, job done right? Well, sometimes. In the real world there’s the way things should “go” and then there’s how things actually play out. Sometimes a crew has an incoming string of cars destined for specific spots BUT not all of the cars presently there have been unloaded. They were “supposed” to be ready but, hey, sometimes shit happens and they aren’t. I call them the “problem children”. What’s a royal pain for a rail crew is an opportunity for a relaxing forty minute operating session that only needs one turnout. Working through this common situation isn’t hard but does take some time.

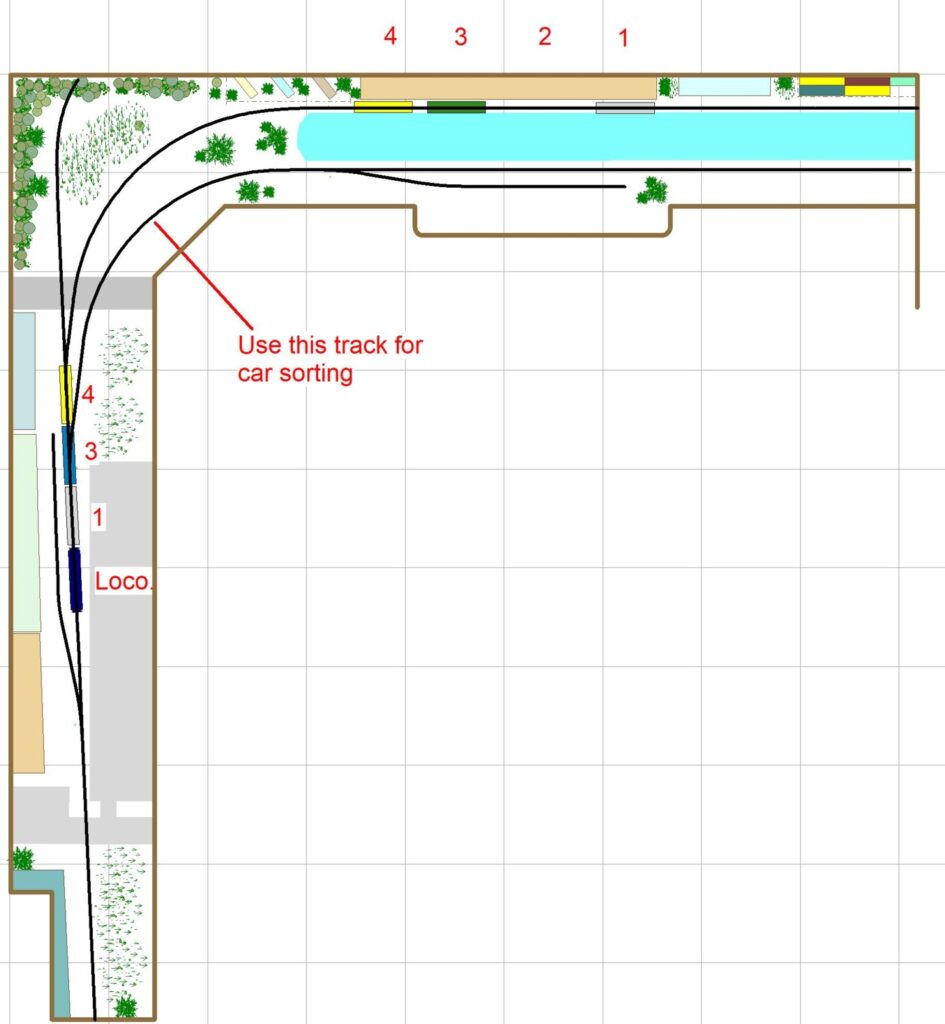

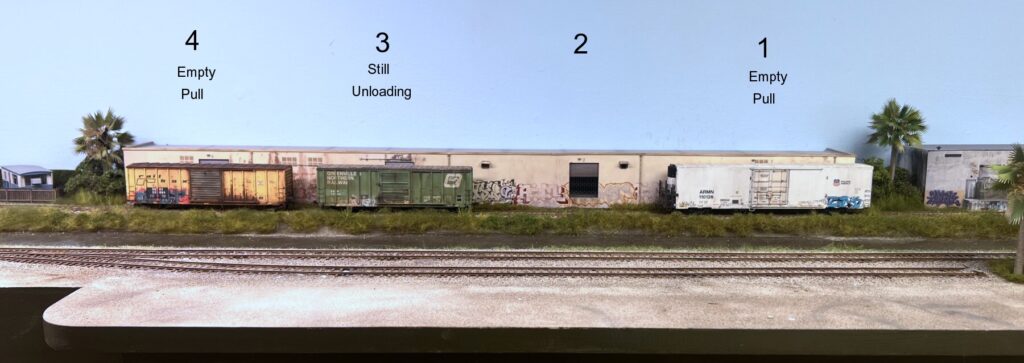

Here’s the graphic of how the op. session is staged to begin with. The glitch is at door 3. We have an incoming load but the car that’s there now hasn’t been unloaded. The foreground track can be used for sorting. What we’ll have to do is spot as many incoming cars that we can. Any incoming loads we don’t have room for will be set nearby to be dealt with on another day.

Different crews use different strategies. I began by using the sorting track to block the incoming string of cars ordering them by the order of the warehouse doors. I had to take into account that the incoming load for door 3 couldn’t be spotted. I then pulled all of the warehouse cars and did some back and forth shuffling until I was done, all of which took me about forty (relaxing) minutes.

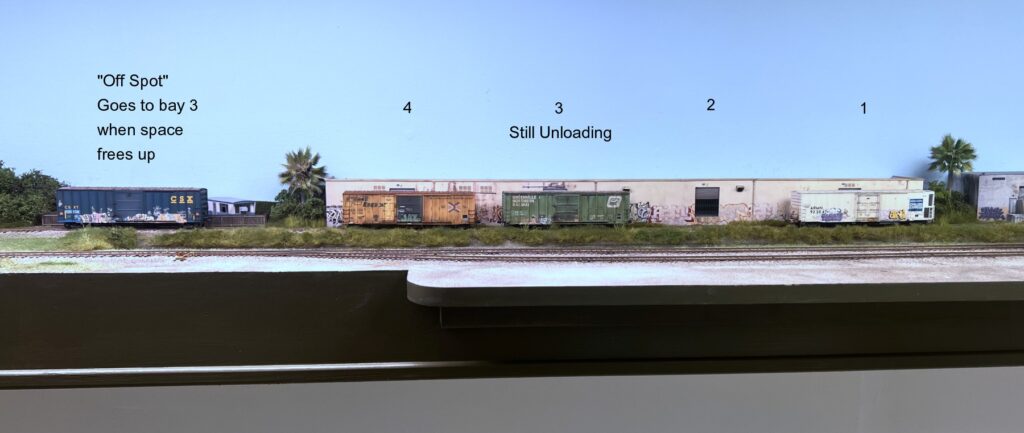

Here’s the end result. The “problem child” is back at door 3. The blue CSX box was supposed to go to 3 but there wasn’t room so I spotted it nearby. The next time the crew comes by the car will be spotted….and depending on CSX’s mood there may be a surcharge for the extra switch. (Note, I should have used different car colors to make my point. I did not. Sorry. FYI I used two different Railbox’s and two separate white reefers during the session)

When I operate my own layout the fun for me is visualizing actually being there. I try to avoid a “grocery list, beat the clock” approach. That’s just too dry, implausible, and takes the fun out of it for me. I try to forget that I’m dealing with six long pieces of plastic that I can easily see from all angles. Rail equipment is bigger than my house, weighs tons, and doesn’t stop on a dime. In the real world sight lines are limited. You have to deal with vehicle traffic at the crossings. It takes time for a crew to walk. There are pauses while the crew does some head scratching and strategizing. Then there’s the environment. There are “hot days” and then there are “Miami hot days” which are so suffocating you can’t understand what it’s like until you’ve been there. Taking all of that into account with just one turnout, one industry, and understanding how rail operations work you can have a thoroughly enjoyable evening running trains.