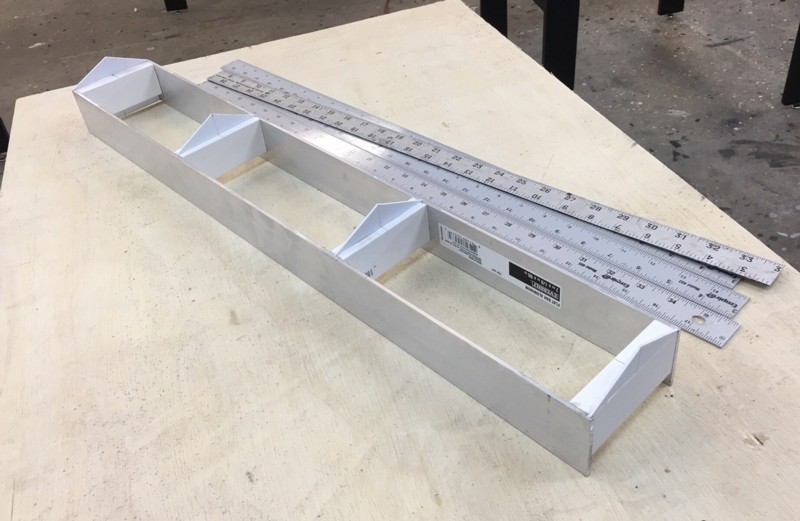

With photo laminates, having a solid core is crucial. I’ve learned the hard way that styrene can get “wiggly” over time. For General Ship Repair I built the core using aluminum bar stock. Spacers were placed inside out of 1 x 2 pvc wood. The ends and roof crown were made of .060″ styrene. Roofs have a tendency to sag. Aluminum yardsticks only cost a few dollars, are solid, and easy to cut so I used those.

Here’s the finished core with the rules in place on the roof.

….and here’s a view from beneath. Traditional CA was used for the adhesive. All done. Solid as a rock!