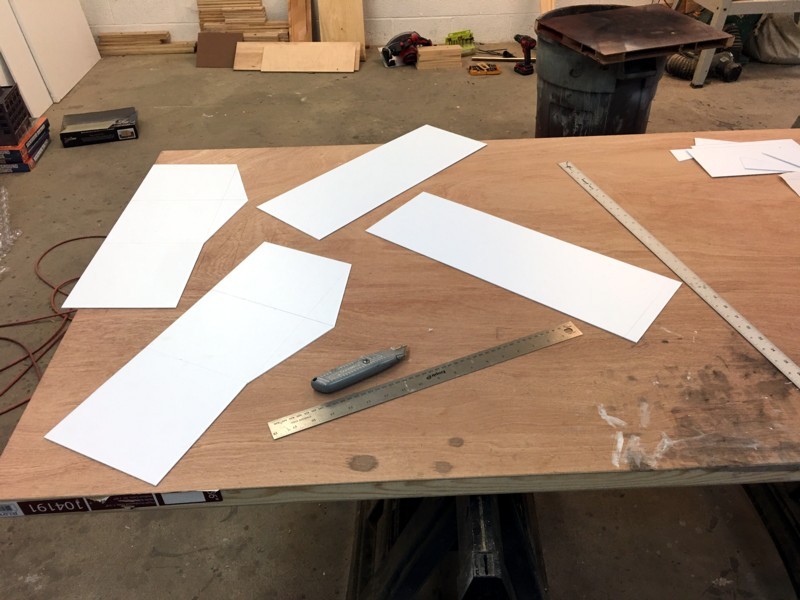

Sometimes the hardest part of a project is simply launching and making those first few pieces. I found a new source for large slabs of .060″ styrene sheet on Amazon. With materials in hand, I’m able to start. For larger structure projects like this I prefer to have a large, clean, work surface to spread things out and keep them organized. Shown above is a 36″ wide hollow core door set on sawhorses. I brought the mockup in from the layout room to serve as a sizing guide.

In this view I’ve carefully marked the dimensions of the side wall slabs and checked for squareness. Styrene sheet is slippery and straight edges have the nasty tendency to slide around in the middle of a cut. To prevent this, I clamped both ends of the yardstick in place, re-checked the cut marks, and then made the cuts.

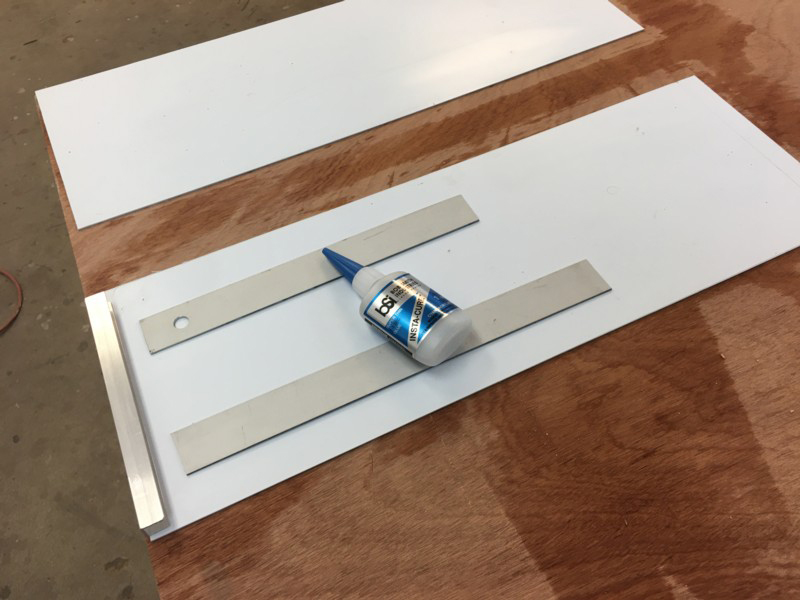

Larger sheets of styrene are very prone to warping, buckling, and wiggling. They need to be stabilized. I spent a few weeks thinking how I wanted to handle the issue. Ultimately I decided to go with what’s worked in the past, aluminum. The corners are 1/2″ C channel from The Home Depot. The other pieces are from an aluminum yardstick which I cut into smaller lengths. Both will be glued to the styrene with CA.