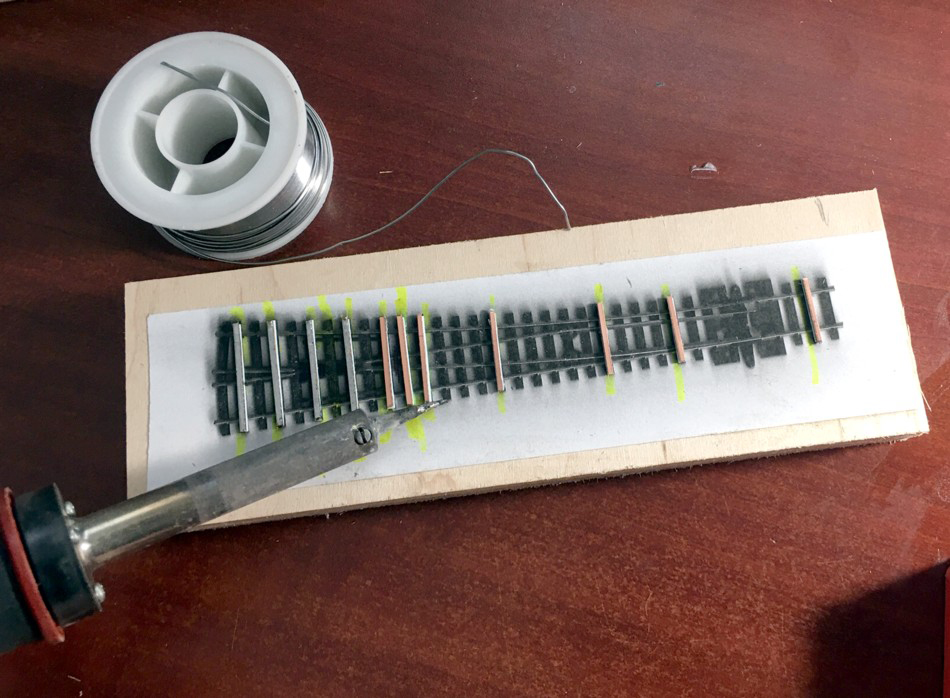

With the turnout rail pieces fashioned, the next step is to prepare the PC ties (they’re used to hold the rail in position). In all other locations traditional wood ties will be used. Printed circuit board is much thinner than flex track or wood ties and the height differential is a bit of a pain when it comes time to place the turnout on the layout. To get around this I glue a piece of .020″ styrene strip to the bottom to bring them up to height. In the photo above, I first glued the styrene shims in place with white glue and then cut the pc ties to length and glued them on top of the styrene strip with CA.

Once the PC ties are shimmed and in position, I then tin them with solder. In the next installment I’ll be soldering the rail to the ties.